Engine Structure

For an effective gasoline engine operation, vaporized gasoline should be mixed with air at the optimal ratio and combusted. This ratio is called the “mix ratio”. When the consumption of air increases to power up, so does that of gasoline, and when the consumption of air decreases to power down, so does gasoline, likewise. Conventionally, the gasoline vaporizer called “Carburetor” had been used to keep the mixture ratio stable. Employing the “Bernoulli’s theory”, the carburetor has a simple structure. With little amount of air supplied to it, the carburetor vaporize only a small amount of gasoline, and with a lot of air, it generates large amount of gas, playing its role of keeping a stable ratio. That means, only the amount of air should be regulated to control the engine power.

Throttle valve

The valve to control the amount of air is called "Throttle Valve", or "Throttle" for short. This may sound familiar to you as "tackling things" sometimes referred to as "at full throttle". By fully opening the throttle valve, the gasoline engine can operate at the maximum power output. Generally, a throttle has a round plate in an induction pipe, and the amount of air is controlled by changing an angle of the plate. Although today's gasoline engines, to go with the trend of energy-saving, above mentioned carburetor is replaced by an electronically-controlled fuel injection device, still air-controlling throttle valves are widely used. Here, the human-to-machine interface to control the opening and closing of the throttle valve is the accelerator, or "gas pedal".

Relation between the accelerator and the throttle valve

In case of a car, accelerator is operated with right foot, and with a motorcycle, right hand. There are several ways to open and close the throttle valve.

Mechanical wire method

With this method, mechanical wire is used to connect the accelerator through to the throttole valve. An operation of pressing down on the accelerator by a driver and opening and closing of the throttle valve work at the ratio of one to one, eliminating operation-related time lags. However, together with the widespread use of the fuel injection (FI) device, it is becoming obsolete.

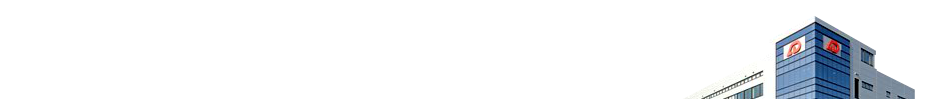

Electronic throttle method (Satellite method)

To eliminate uncomfortable feelings from accelerating operations, the mechanical wire is left as is while the pulling force of the wire is converted into rotary motion. Then, the rotary angle is detected by the APS (Accelerator Position Sensor) and the signal is sent to the ECU (Engine Control Unit). With this method, control of the electronically-controlled throttle and fuel injection device via ECU becomes possible.

This allows the ECU to control the opening of throttle valve in addition to adjusting the spray amount of gasoline, enabling the system to adjust the amount of both air and gasoline in different situations. This method also contributes to better mileage, switching of engine characteristics, and better control of traction and/or launch, etc.

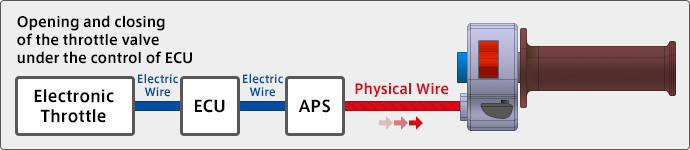

Electrical throttle method (Mechanical wireless method)

With a more advanced method, the mechanical wire is completely get rid of and the Accelerator Position Sensor (APS) function is built in the accelerator itself. By removing the mechanical wire, tubing and wire adjustment become unnecessary, contributing to the better installability to the vehicles. Also, with less mechanical parts, higher reliability can be expected. At Asahi Denso, we realized extremely high reliability by adopting the non-contacting magnetic sensor. Furthermore, much concerned uncomfortable feeling users might experience once the mechanical wire is removed, through various studies, we succeeded in generating the operational torque that is in no way inferior to the conventional mechanical wire.

Asahi Denso's Accelerator Position Sensor

We, Asahi Denso have developed the Accelerator Position Sensor (APS) for race motorcycles, and with knowhow we achieved from that experience, we are fully confident in the accuracy of rotary angle detection. As we accumulated various expertise on operational feelings, we can make products that suit customer's request and needs. Not only the APS, we have also designed and produced grips, ECUs (Electronic Control Unit), actuators, electronic throttles, and the electronic control system integrating all of these devices. We can also replace a part of your control system with ours. If you are considering building an electronic control system, enhancing reliability and accuracy, or prefer to take part in the development from the prototype stage, please contact us at any time.

![Asahi Denso Co., Ltd. | The special maker for Human and Machine Interface [Open the way]](/uploads/op-asahidenso/en-logo.png)